A lokacin da saƙa 2 + 2 hems a kan rijiyar haƙarƙari, yadda ake daidaita idan gaban da baya loops suna da wannan sakamako?

Hanyoyin da ke Matsakaicin masana'anta tare da irin wannan sakamakon gaba da baya

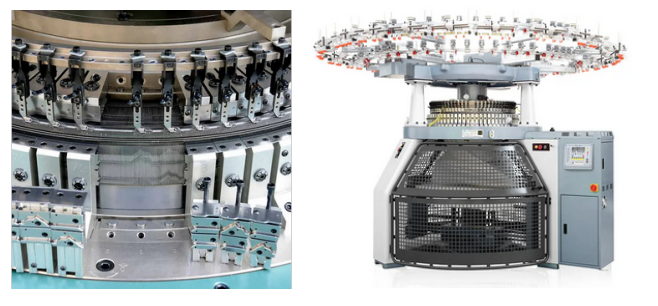

Lokacin da debugging samiyoyi tare da irin wannan salon a garesu na zane, ya kamata mu yi amfani da hanyar saƙa. Dalilin wannan shine don kammala tsarin haramtaccen tsarin buga kiran waya da allon silinda a lokaci guda don guje wa madaukai na gaba da baya wanda ya haifar da canja wurin madaukai. Tsaurin ba daidai bane. Bambanci tsakanin shi da kuma saƙa-da-yankan saƙa shine: yana magance matsalar rashin daidaituwa na kayan gaba da baya. A karkashin tsawon daya lafar, masana'anta da masana'anta da guted-yankan yana da karamin nisa da kuma kyau elasticity; Mafi karancin zaki don saƙa shine ya fi tsayi da ƙananan zaren da za a iya jefa bayan cizo.

Hanyar daidaitawa Lokacin da kuma ketunging Sauran da ake buƙata 2 + 2 Mabir

A lokacin da saƙa 2 + 2 hems tare da mafi girma gram ingancin, lokacin da duk yanayin da suka dace da matsayi mai dacewa na sassan iri ɗaya ne, ya ninka da ƙimar gram. Amma a cikin wannan tattaunawar, lambar kiran ta dace da Cylinderder. Canjin matsayi nasa ne na mahimmancin yanayin saƙa, bai dace da kwatancen dangantakar da ke tsakanin yanayin da ingancin gram a ƙarƙashin yanayin. Ainihin yanayin kuma yana tabbatar da cewa a ƙarƙashin yanayin tsayinsa iri ɗaya, nisa daga cikin masana'anta wanda aka saka ta hanyar saƙa gefe-gefen-gefen saura da ƙimar gram ya fi girma. Wannan shine sakamakon canjin yanayi ne. A lokacin da saƙa a cikin matsayi, koda kuwa an daidaita karancin zaren, ingancin gram bazai yuwu sama da ƙimar gram ba lokacin da aka saka tsayin daka na al'ada.

A lokacin da saƙa 2 + 2 hems da spandex, hanyar ciyar da Interandex na injin din ya daidaita kuma a gyara shi. Hanyar haƙarƙan fitila da spandex ita ce ciyar da yarn da aka tsara a cikin maɓallin bugun kiran, da kuma daidaita matsayin da keɓewa don hana allurar silinda. Yarn SPandEx. Wannan hanyar a bayyane yake ba mai yiwuwa bane a daidaita matsayin. Yin amfani da wannan hanyar zai haifar da keɓaɓɓen sirinji don ku ci yarn spandex. A lokacin da saƙa a cikin kishiyar m, idan kuna son ƙara spandex zuwa allura na kiran, zaka iya amfani da wata hanyar, wato, spandex yarn ne daga sama da allura ta buga da a bayan allura na silinda. Ta wannan hanyar, yana yiwuwa a hana silsi na allura daga cin yarn spandex. Koyaya, yin amfani da wannan hanyar don ƙara yarn SpandEx yana da wasu buƙatu don injin. Abubuwan da ake buƙata kamar haka: na farko, zaɓi na allurar bidiyo ba zai iya amfani da ɗakunan saƙa tare da tsawon harshe ba. Harshen da densabobi masu dogon latch suna rufe a baya yayin da suke ba su da tushe. , Yana da sauƙi matsa yatsan spandex yar yar don samar da yanke, kuma spandex zai karye. Abu na biyu, akwai wasu buƙatu don ƙirar alwatika na kiran, kuma manufar ita ce sarrafa lokacin rufewa ta hanyar.

Ba dole ba ne ci bit bit ba lallai ba ne warware matsalar zane ba. A halin yanzu, allurar makarantu mafi yawan baki saƙa a kasuwa a kasuwar siyar da wasu allura, wannan shine, manufar karami, manufar ita ce, manufar kananan tsarin madaukai a lokacin da ba a tsare ba. Saboda ƙaramin allura shi ne, ƙarancin m da allurar cajin kiran shine lokacin da ba a buƙatar canjawa wuri daga tsohon madauki na allura na allura allura. Koyaya, an canza sabon abu har yanzu ba wanda zai iya zama. Kawai canji ne a cikin adadin canja wuri, kuma mafita ga matsalar zane shine kawai na gida, ba maganin masarufi ba.

Wani karamin injina sun amince wata hanyar da za a magance wannan matsalar. Tunanin shine: tunda madauki canja wuri ba makawa ne, bari ya faru. Abinda yakamata a yi shi ne su kara wani matakin saƙa bayan canja wurin madauki ya ƙare sakamakon canja wurin madauki a lokacin da ba a tsare ba. The method is: when the dial needle and the needle cylinder needle complete the looping and enter the next knitting action, let the dial needle perform a respiration layman's action, and at the same time let the cylinder needle have a downward pressing and tightening action, so that the dial needle and the needle The cylinder needle performs another loop transfer to eliminate the unfair distribution of the loops caused by the transfer of the loops during the looping process of allon kiran da allurar silinda.

Lokaci: Oct-09-2021